Hasung has emerged as a transformative force in the precious metal production industry, thanks to its innovative metal casting machines. These machines are designed to address the evolving needs of jewelers, refineries, and industrial manufacturers by offering a blend of precision engineering, advanced automation, and robust safety features. Hasung’s commitment to technological advancement has set new benchmarks for efficiency, product quality, and operational reliability across the sector.

Versatility Across Precious and Industrial Metals

One of the standout features of Hasung metal casting machines is their remarkable versatility. The equipment is engineered to handle a broad spectrum of metals, including gold, silver, copper, platinum, palladium, and a range of alloys. Depending on the specific model, users can select machines optimized for both high and low melting point metals, making them suitable for everything from jewelry production to industrial component manufacturing. This flexibility allows businesses to adapt quickly to changing market demands without the need for multiple specialized machines.

The Science of Vacuum and Inert Gas Casting

Central to Hasung’s technological edge is its use of vacuum and inert gas environments during the casting process. By creating a vacuum and introducing inert gases such as argon or nitrogen, the machines effectively eliminate oxidation and the risk of impurities mixing with the molten metal. This controlled atmosphere ensures that the final cast products are of the highest purity and structural integrity, free from porosity, bubbles, or surface defects. The result is a consistently superior finish that meets the rigorous standards of both investors and artisans.

Automation and Intelligent Control Systems

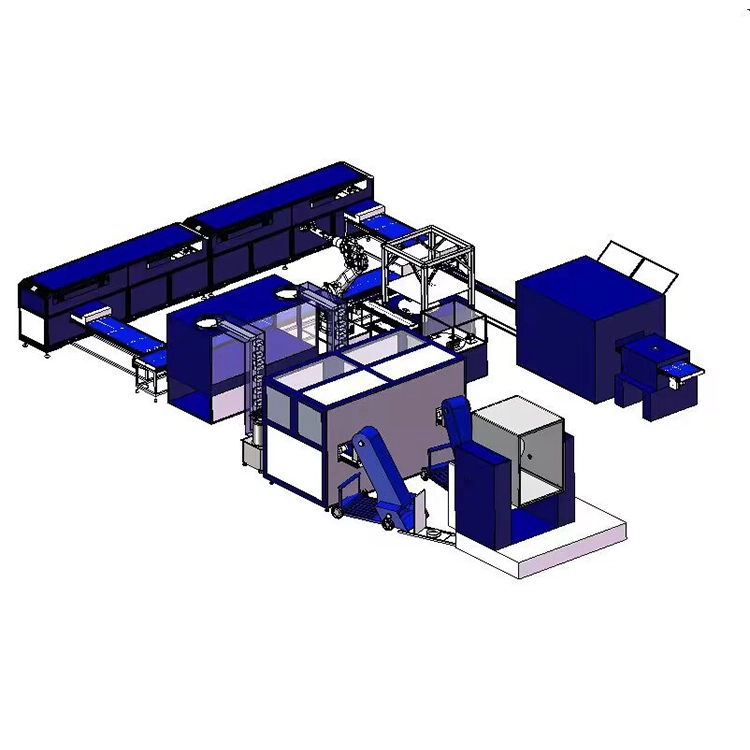

Hasung machines are equipped with sophisticated automation and control systems, including PLC (Programmable Logic Controller) technology and PID (Proportional-Integral-Derivative) temperature regulation. These systems enable precise control over every stage of the casting process, from melting and pouring to cooling and product ejection. Operators benefit from user-friendly interfaces, often requiring just a single button to initiate complex casting cycles. This high degree of automation not only boosts productivity but also minimizes the potential for human error, ensuring uniform results with every batch.

Enhanced Efficiency and Production Capacity

Efficiency is at the heart of Hasung’s design philosophy. The machines are built to accommodate both small-scale and large-scale operations, with capacities ranging from just a few kilograms to as much as 30 kilograms per cycle. Rapid heating and melting cycles, combined with optimized energy usage, enable manufacturers to increase throughput while reducing operational costs. The robust construction of Hasung machines, often featuring stainless steel bodies and high-quality core components, ensures durability and stability even under continuous, high-volume use.

Quality Assurance and Superior End Products

Hasung places a premium on quality assurance, integrating multiple features that guarantee the excellence of the finished products. The vacuum and inert gas system prevents oxidation, while advanced mixing mechanisms ensure uniform alloy composition. Accurate pressure timing and self-diagnosis functions further enhance the reliability of each casting. The outcome is precious metal bars, ingots, and jewelry components that exhibit exceptional surface smoothness, high density, and minimal metal loss—qualities that are highly prized in both the investment and luxury goods markets.

User-Centric Design and Maintenance

Ease of use and maintenance are core aspects of Hasung’s product philosophy. The machines are designed for straightforward operation, often with automated or semi-automated features that simplify the casting process. Maintenance is facilitated by accessible components and intelligent diagnostic systems, reducing downtime and extending machine lifespan. Hasung’s dedication to customer satisfaction is evident in its ongoing support and continuous product improvement, making it a trusted partner for businesses seeking to elevate their metal production capabilities.

Shaping the Future of Precious Metal Manufacturing

With its innovative approach and relentless focus on quality, Hasung is truly revolutionizing the field of precious metal production. By combining scientific rigor with practical engineering, Hasung metal casting machines empower manufacturers to achieve new levels of efficiency, purity, and product excellence. As the industry continues to evolve, Hasung’s technology stands poised to shape the future of how precious metals are crafted, refined, and brought to market.