In the fiercely competitive world of custom apparel, a brand's identity often comes down to its colors. Yet, many manufacturers impose strict limitations on color palettes, forcing brands to simplify logos and compromise their vision. This is where OKAY SOCKS sets itself apart, wielding what many consider to be a trade secret: genuinely unlimited color variation. This capability is not a marketing gimmick but the result of two distinct, purpose-built production systems working in concert. By offering both sophisticated yarn dyeing for knitted-in designs and state-of-the-art sublimation printing for all-over graphics, OKAY SOCKS provides clients with a freedom of expression that transforms socks manufacturer from mere accessories into true brand canvases, all while maintaining exceptional quality and durability.

The Dual-Technology Engine: Beyond a Single Process

The foundation of unlimited color lies in a manufacturer's technical versatility. Many factories specialize in one method, which inherently comes with constraints. OKAY SOCKS operates on a dual-technology model. The first is traditional, high-precision knitting using pre-dyed yarns, which excels at creating durable, textured patterns like stripes, logos, and argyles . The second, and the true game-changer for color, is advanced sublimation printing . This process uses heat to transfer dye directly into the fibers of the sock, allowing for photographic detail, intricate gradients, and patterns that use every color imaginable without increasing complexity or cost . By mastering both, OKAY SOCKS can recommend the perfect technique to match any creative brief.

Sublimation Printing: Where Imagination Meets the Fiber

Sublimation printing is the cornerstone of achieving unlimited colors. Unlike a surface print that sits on top of the fabric, sublimation dye becomes part of the sock's polyester fiber through a heat transfer process . This means the design won't crack, peel, or fade noticeably with washing, as it's ingrained within the material itself. The technical implication is profound: if a design can be created digitally, it can be reproduced on the sock . This enables photorealistic images, complex digital art, and seamless, wraparound patterns that cover the entire garment without unsightly white gaps or seams—a feat difficult to achieve with other methods . For brands with vibrant, detailed logos or artists creating wearable art, this process removes all traditional barriers.

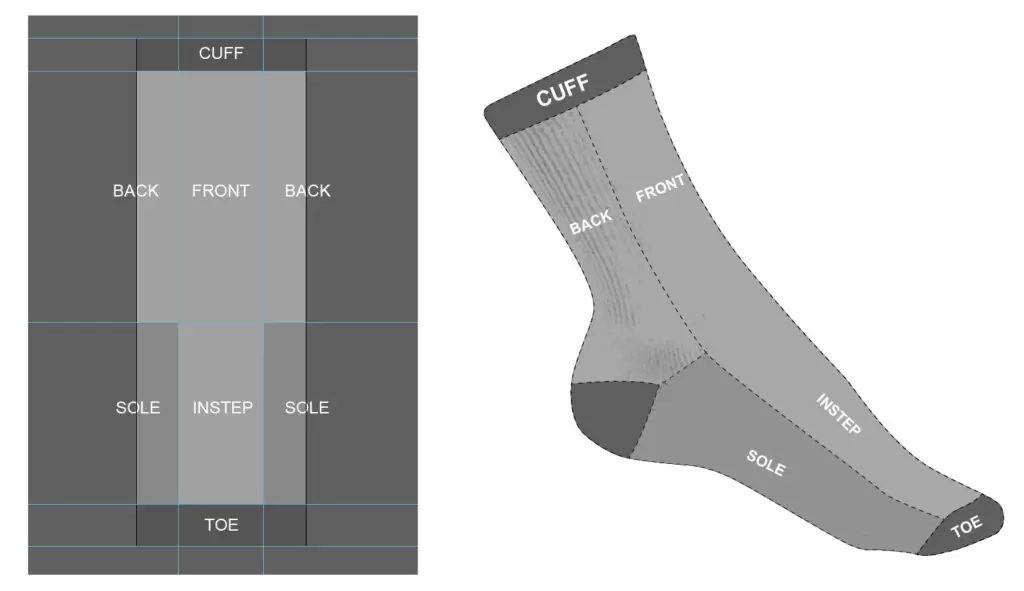

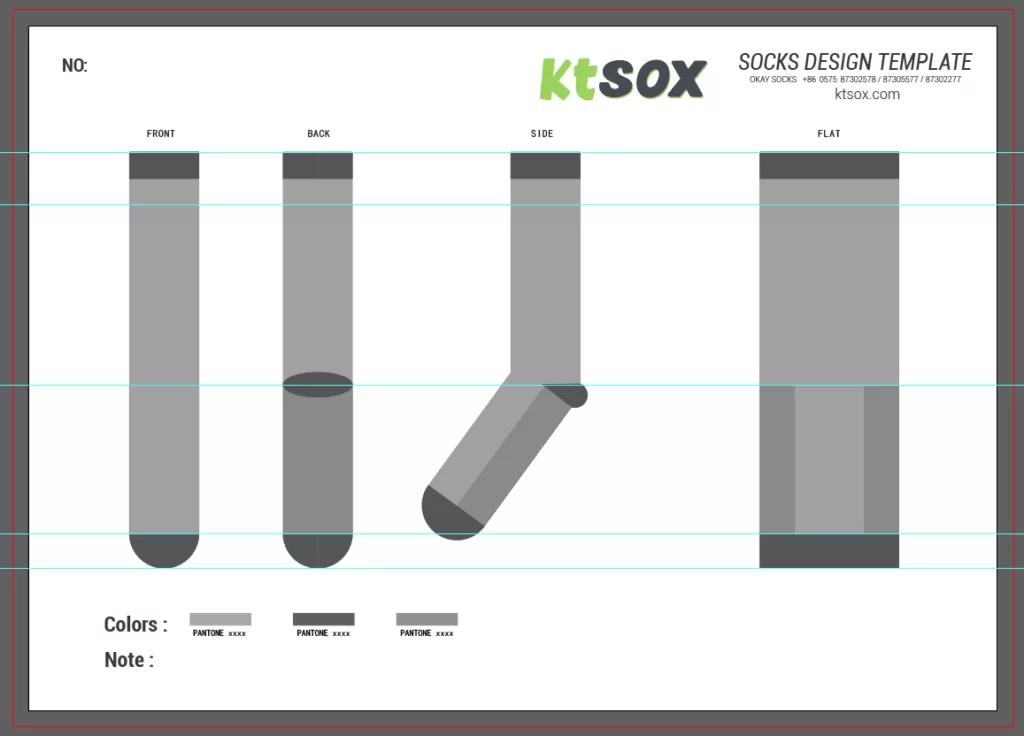

Custom Dyeing: Precision for Brand Integrity

For projects where a specific, consistent brand color is non-negotiable, OKAY SOCKS's custom yarn dyeing service offers pinpoint accuracy . This is crucial for corporate clients, sports teams, and universities where Pantone-matching a logo color is essential. The factory controls the dyeing process in-house, ensuring the yarn is colored to exact specifications before it is ever knitted into a sock . This method integrates the color into the very structure of the sock, resulting in a classic, premium feel with excellent longevity. It represents unlimited color variation in a different form: the ability to create any specific shade on demand, not just use many shades in one design.

Overcoming Traditional Knitting Limitations

To appreciate the revolution of unlimited color, one must understand the limitations of standard jacquard knitting. In this traditional method, each color in a design requires a separate yarn feed on the knitting machine. Designs are often restricted to around 4-8 colors to maintain structural integrity, affordability, and a comfortable fit, as too many yarn cuts inside the sock can create bulk . OKAY SOCKS certainly offers this high-quality jacquard service for classic styles , but their sublimation option liberates designers from these constraints entirely. With printing, a design featuring 20 colors is no more difficult to produce than one with two, empowering unparalleled creative ambition .

Strategic Application: Matching Method to Vision

The real secret is knowing how to apply these technologies strategically. OKAY SOCKS guides clients to the best method for their goals. For a bold, all-over graphic tee-style design or a detailed landscape, sublimation printing is the unequivocal choice . For a corporate polo shirt stripe, a classic argyle, or a small embroidered logo requiring a specific, textured finish, knitted or dyed yarns are superior . This consultative approach ensures the final product is not only beautiful but also perfectly suited to its intended use, whether it's for high-performance athletic wear, formal dress socks, or promotional merchandise.

From Concept to Color-True Reality

Leveraging this capability is a streamlined partnership. Clients begin by sharing their vision—whether it's a complex digital file, a simple logo, or just a concept . OKAY SOCKS's design team then provides free, unlimited revisions on digital mockups, ensuring the artwork is optimized for the chosen production method . For ultimate confidence, they can produce a physical sample based on the confirmed design before bulk production begins, guaranteeing color and detail accuracy . This end-to-end service demystifies the process, turning the promise of unlimited color into a tangible, wearable reality.

In an industry where compromises are often expected, OKAY SOCKS's commitment to unlimited color variation represents a fundamental shift. It is a declaration that a brand's visual identity should never be diluted for manufacturing convenience. By investing in the dual engines of sublimation printing and custom yarn dyeing, they provide more than a production service; they offer a partnership in unbounded creativity. For any business or creator looking to make a vivid, lasting impression, this secret is the key to turning socks into a powerful, colorful statement.